Babbits

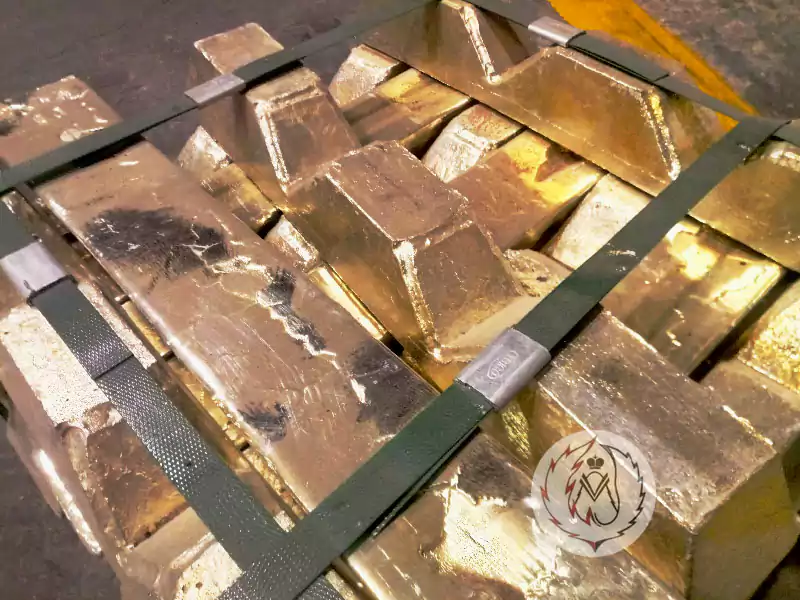

SPA PHOENIX manufactures babbitts in ingots, and in any other form by customer order.

Babbitts production is carried out according to high standards in strict compliance with technological processes and is able to provide large supply volumes.

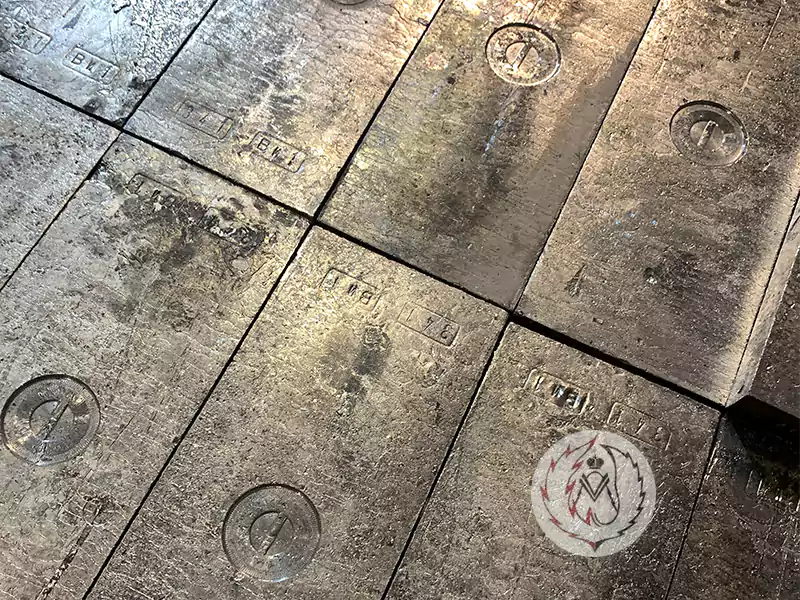

Each batch of babbitts manufactured in our facilities is analyzed in an accredited specialized spectral laboratory for the analysis of non-ferrous metals and alloys. The laboratory confirms the chemical composition of babbitts (purity) with a passport for each batch manufactured.

Steps in working with us:

1.You make an order in any way convenient for you (by phone or email).

2.We agree on the scope of supply and conclude a contract.

3.We manufacture products.

4.We check the quality of finished products in our own laboratory.

5.We deliver your order by the optimal mode of transport.

The variety of babbitt grades, our production, allows you to choose their chemical composition based on your needs.

Depending on the grade, babbitts have different characteristics:

- The strongest: where the maximum amount of lead 90% – withstands shock loads, such metal is used in nodes and parts of tractor engines.

- Limited to impact loads. Bearings based on it are used for quiet operation and at peripheral speeds up to 120 m/s, the ambient temperature should not exceed 70 ºC.

The most common application is the manufacture of bearings. Bearings can be used in the manufacture of steam turbines, rolling mills, compressors, electric motors, hydraulic turbines and sawmill frames, crosshead, frame and whorl bearings and high-speed diesel engines, propeller shaft support bearings, turbochargers, turbo pumps, compressors, and for marine and stationary steam engines over 500 kW. Separately, we should mention the manufacture of heavy machinery bearings designed for high speeds and dynamic loads at T° up to 70° C, eccentrics of cone crushers of large crushers, bearings of high-speed pinion stands.

Some types are used exclusively for filling the bearings of machines of considerable power, where a high viscosity value and the lowest coefficients of friction are required. These bearings allow high circumferential speeds of up to 50 m/s. The optimum operating temperature is 75ºC.

Delivery of products SPA Phoenix

Babbits delivery to the customer is carried out anywhere in the world, by rail, transport companies.

You can pick up the paid order from our warehouse on your own: St. Petersburg, Metallostroy village